Our initiatives focus on building a more sustainable tomorrow, making a difference globally. #TechnologyThatCares

Electrosteel Castings Ltd has been awarded the 'Iconic Brands of India 2023' by ET Edge, a Times Group initiative, reflecting our commitment to improving lives.

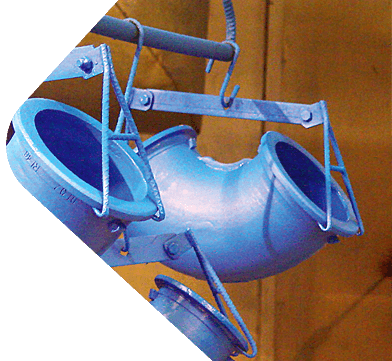

Internationally certified superior quality DI Pipes and Fittings are customized as per requirements.

Electrosteel caters to 110+ nations across the Indian sub-continent, South East Asia, Middle East, Europe, USA, South America and Africa.

Adhering to strict quality and compliance guidelines to deliver the best

Focused on delivering superior quality products, Electrosteel Castings is internationally accredited, maintaining the approval of its quality system and products.

JSS awards recognizes and acknowledges water warriors who have championed in water related initiatives.

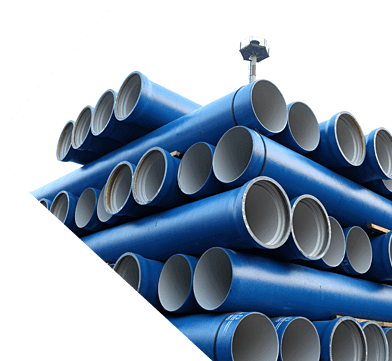

Pioneer in the production of Ductile Iron Pipes in India.

Electrosteel Castings Limited (ECL) is a pioneer in the production of Ductile Iron Pipes, Flange Pipe in India, with a strong presence in over 110+ countries across the globe.

Know more

Know more

Internationally certified superior quality DI Pipes and Fittings

DI Pipes Fittings & Special Other ProductsElectrosteel Group Wins ET 'Iconic Brands of India 2023' Award

Electrosteel Castings Ltd has been conferred the 'Iconic Brands of India 2023' Award, by ET Edge, an Eco...

Harnessing Water Power

Mr Sunil Katial, our CEO appears in the Economic Times on the occasion of "World Engineers' Day".

...

Jal Sevak Samman, 2023

A unique initiative, undertaken on the eve of World Environment Day, in the presence of an esteemed audi...

#ElectrosteelCastingsLtd France participated in a sports event in Tarascon, France championing the c ..

#ElectrosteelCastingsLtd sponsored the 5k Fitness Fusion Campus Run at IIT Tirupati, on April 14. 4 ..

#ElectrosteelCastingsLtd participated in a groundbreaking seminar and workshop on ‘Planning & Mana ..

#ElectrosteelCastingsLtd's JAL SEVAK SAMMAN Awards are back! In an age of dwindling natural resourc ..

#ElectrosteelCastingsLtd (UK) partnered with Expect Amazing Ltd, a children’s book specialist, to ..

#ElectrosteelCastingsLtd is proud to partner the flagship central govt housing project, Pradhan Mant ..

Shubho Naboborsho from all of us at #ElectrosteelCastingsLtd! #bengalinewyear2024

Jal Sevak Samman (#JSS), an initiative #ElectrosteelCastingsLtd began last year to recognise the eff ..

#Eid greetings to all, from #ElectrosteelCastingsLtd. www.electrosteel.com

The world-famous Christian Medical College contacted #ElectrosteelCastingsLtd for help, to end its r ..

Even the Swiss applaud the highest #ElectrosteelCastingsLtd standards! A coalition of municipalit ..

#ElectrosteelCastingsLtd USA was delighted to participate in the #PacificWaterConference2024 recentl ..

#ElectrosteelCastingsLtd is an active participant in the Govt of India’s national #JalJeevanMissio ..

#ElectrosteelCastingsLtd is proud to announce the successful completion of a major water infrastruct ..

Tee off with #ElectrosteelCastingsLtd! . The Electrosteel Tolly Putting Championship 2024 saw an in ..

#ElectrosteelCastingsLtd participated in the 3rd Roorkee Water Conclave, 'Responsible Water Manageme ..

Happy Holi from #ElectrosteelCastingsLtd! Wishing you the most joyous celebration with friends and f ..

#ElectrosteelCastingsLtd invites you to join the global #EarthHour movement! For one hour this eveni ..

#ElectrosteelCastingsLtd celebrated #WorldWaterDay2024 with much gusto! . For our #GhatCleanUp driv ..

Let's #fixtheleak together! #ElectrosteelCastingsLtd, in association with Active Citizens Togethe ..

Bada Sahab. Shri Ghanshyam Ji Kejriwal. The legend who created #ElectrosteelCastingsLtd. The pionee ..

#BREAKINGNEWS #ElectrosteelCastingsLtd was felicitated at the World HRD Congress for its commitment ..

#ElectrosteelCastingsLtd has always believed in the unifying and inspirational power of sports, to m ..

#ElectrosteelCastingsLtd participated in #AquaPro, the Swiss national exhibition on water management ..

As part of the ongoing #InternationalWomensDay celebrations at #ElectrosteelCastingsLtd, we quizzed ..